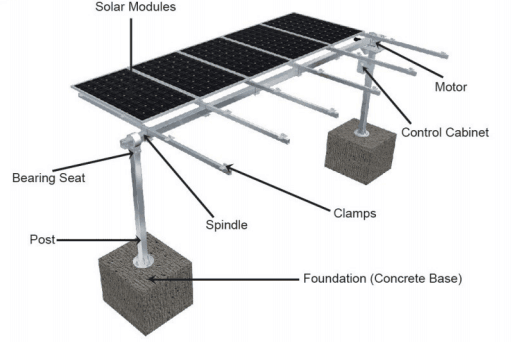

The Smart Horizonal Single Axis Tracking System will make solor modules to face direct radiatoin from the sun by its single spindle, which changes the position and angle of the panels,to improve photon-to-electron conversion efficiency.

The Smart Horizontal Single Axis Tracking System is designed and developed for large scale solar park,and can be widely used in low-latitude regions.This system will make whole array track automatically by a set of driving device and controller, and the unique linkage type tracking mechanism as well as the maintenance-face slewing bearings ensure its high stability, low failure rate and low maintenance cost etc. Compared with the traditional fixed mounting systems, this system will be an ideal choice for large scale solar projects, due to its 20% increase in the power generation

Features of Tracker Structure

1.Higher efficiency:the power generation will increase by 20-30%,compared with fixed mounting systems;

2.Good performance in wind resistance and adaptability; easy and flexible installation;

3.High reliability and tracking accuracy; stable performance;

4.The ventilate channels between adjacent solar modules will reduce the windward load on tracker structure,and ensure the balance of tarcker;

5.Transmission is made from self-lubricating material,ensuring its atability;

6.Widely applicable for polycrystalline and concentrating photovoltaic modules.

| Description |

Parameter |

Description |

Parameter |

| Mounting Structure: |

Horizontal Single Axis Tracking System |

Power Supply: |

DC24V |

| Installation Volume: |

<25KWp |

Driving Method: |

Slewing Speed Reducer |

| Tracking Range of Motion: |

±60º |

Tracking Accuracy: |

±1º |

| Tracking Algorithm: |

Astronomical Algorithms+Tilt Sensors |

Control System: |

Single Chip Microcomputer |

| GPS Module: |

Acquire longitude,latitude and accurate time automatically, and be compatlble with Beidou Satellite Positioning System. |

| Power Generation Increase: |

About 20% |

IP Grade: |

IP65 |

| Anti-Corrosion Treatment: |

HDGI+Aluminium |

Foundation: |

H Beam/Cement Piles |

| Maximum wind load: |

42m/s |

Wind Resistance: |

<22m/s |

| Wind Protection: |

Supported |

Positoin Return Mode: |

Supported |

| Rain Cleaning Mode: |

Supported |

Snow Removal Mode: |

Supported |

| Safety Protection: |

Overload/Position Limitation |

Communication Interface: |

RS485 |

| System Operating Temperature: |

-40~85℃ |

|

|

Features of Control System

- Fully automatic tracking without manual debugging;

- Wide range of tracking angle, to improve the power generation;

- Its good environmental adaptability avoids the interference from cloudy day;

- The function of automatically laying flat or automatically turning eastward is optional at night;

- Equipped with GPS system to ensure the accuracy of timing;

- The high weather resistance contributes to safe and steady operation between -40℃and 85℃;

- The excellent electromagnetic compatibility design makes it highly reliable and stable;

- Equipped with manual control model, to adjust the tracking angle on request;

- RS485 communication interface can read the device data and current running status through software;

- Telecommunication and group control on multiple equipments are available;

- Errors will be automatically identified , and cause automatic protection and automatic alarm;

- Quadruple overcurrent protection ensures the safely of the whole system;

- It can be configured according to user's special requirements.

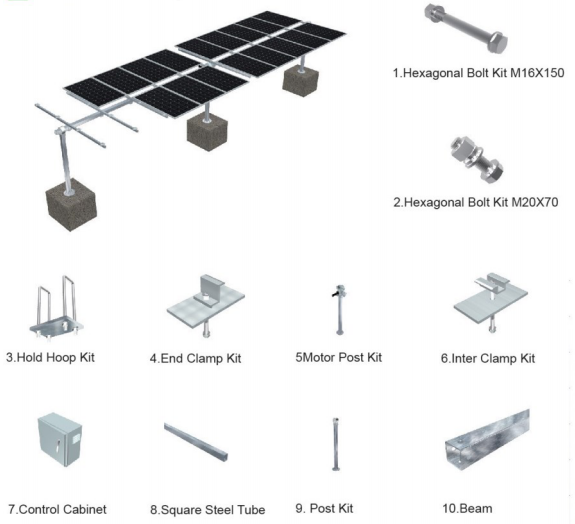

| Component List |

| 01 |

Hexagonal Bolt Kit M16X150 |

02 |

Hexagonal Bolt Kit M20X70 |

03 |

Hold Hoop Kit |

| 04 |

End Clamp Kit |

05 |

Motor Post Kit |

06 |

Inter Clamp Kit |

| 07 |

Control Cabinet |

08 |

Square Steel Tube |

09 |

Post Kit |

| 10 |

Beam |

|

|

|

|